Engineered for precision and quiet operation, the GIS GMF Electric Trolley ensures smooth horizontal movement of hoists and loads along the beam. Compact and robust, it features an enclosed gear motor and adjustable flange widths for seamless integration with GIS hoists. Its Swiss-made quality and low-maintenance design make it a top choice for industrial applications where accuracy, cleanliness, and reliability are key.

- Electric trolleys for steel beams

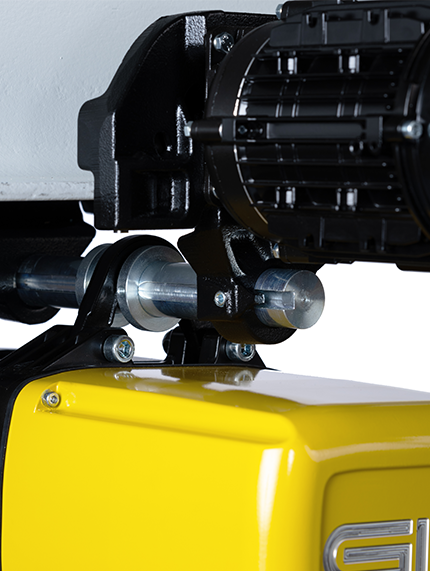

- Side plates made of cast iron with fall and climbing protection

- Load wheels made of cast iron, with ball bearings

- Flange width infinitely variable

- 1 or 2 travelling speeds

- Protection class IP54

Request a quote

Technical Specifications

| Maximum load capacities | GMF1250: 1250 kg, GMF2500: 2500 kg, GMF5000: 5000 kg, GMF6300: 6300 kg |

| Flange widths | GMF1250: 70 - 240 mm, GMF2500: 88 - 300 mm, GMF5000 / 6300: 91 - 300 mm |

| Minimum curve radius (with carrier roller) | GHF1250: 1300 mm, GHF2500: 1800 mm, GHF5000 / 6300: 2200 mm |

| Standard voltages | 3 × 400 V / 50 Hz, 3 × 230 V / 50 Hz 1 × 115 V / 50 Hz, 1 × 230 V / 50 Hz |

| 3 phase motor / 1 phase motor | 1 or 2 speeds / 1 speed |

| Control | 42 V low voltage control |

| Protection class | IP54 |

| Material | Side plates and load wheels made of cast iron |

| Load wheels | Load wheels for flat running surfaces |

| Support bolt | Galvanised support bolt |

| Protection | Fall and climbing protection |

| Control switch | 4 button control switch with emergency stop and external strain relief |

| Control cable length | 2 m |

| Isolation class (motor) | F |

| Brake | DC spring-loaded brake |

Customer's Benefit

The GMF1250 - 6300 electric trolleys are designed for maximum flexibility and longevity:

The larger diameter of the load wheels, the helical gear parts and load wheels which can be matched to the beam surface ensure a longer service life and optimum running properties.

The flange width is infinitely variable by means of a new type of adjustment system and can be fixed easily by using the a locking function.

Due to their good handling characteristics and their longevity, GIS trolleys are often used by our customers as components for end carriage of underslung travelling cranes.

Accessories & Options

- Trolley in corrosion resistant version

- Trolleys in ATEX version

- Direct control, special control

- Radio remote control

- Festoon mounted pendant control box

- Frequency inverter

- Worldwide operating and control voltages

- Special speeds available on request

- Travel limit switch 1 or 2 stages

- Carrier rollers for cornering

- Convex load wheels made of cast iron

- Plastic load wheels

- Load wheels made of stainless steel

- Special support bolts for special flange widths

- Gear grease for low temperature use / food industry

- Temperature monitoring to prevent the motor from overheating

- Protection class IP65

- Counterweight modularly expandable

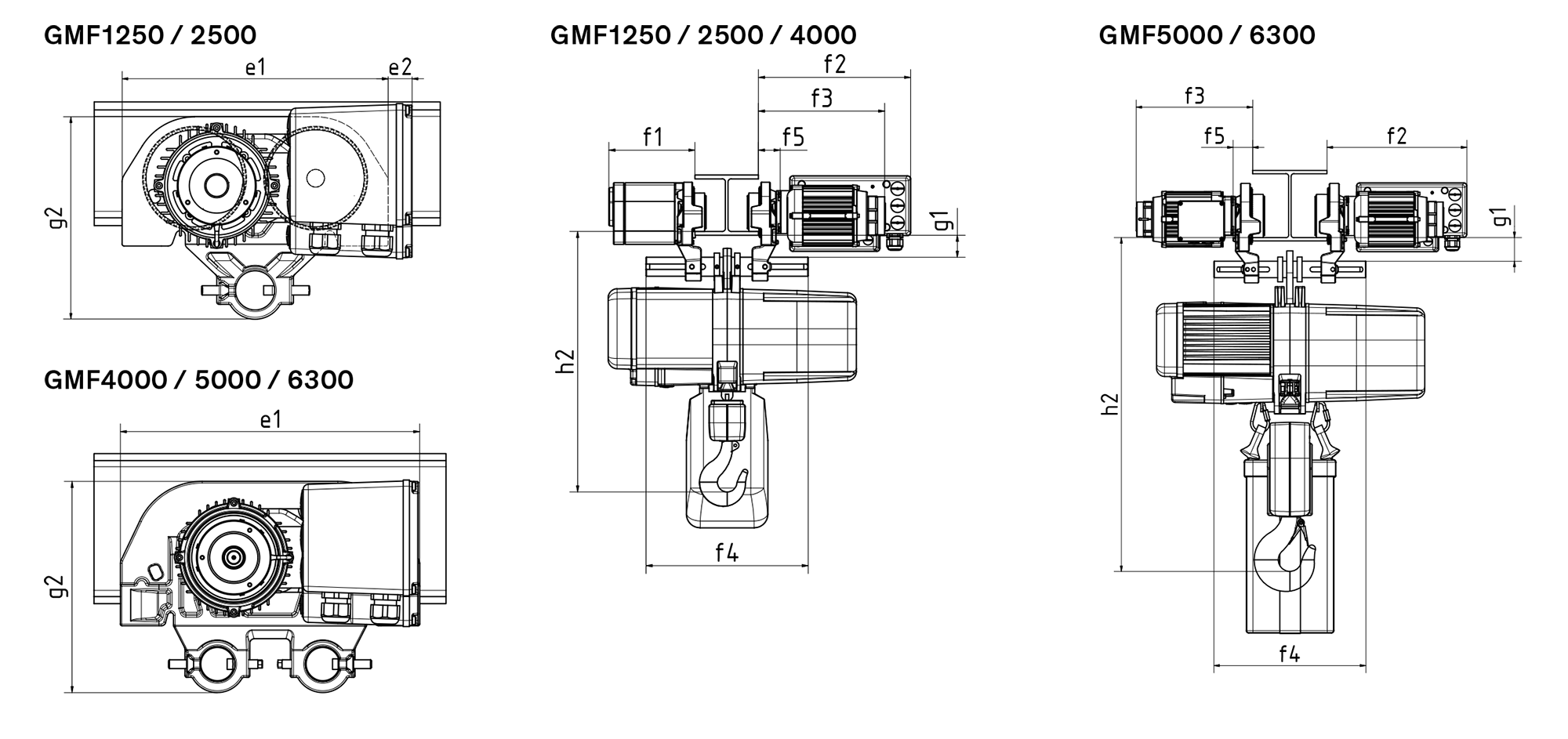

| ||||||||||||||||

| Models | Capacity | Speed(s) m/min | Weight | e1 | e2 | f1 | f2 | f3 | f4 | f5 | g1 | g2 | Adj. flange width (mm) | Min. curve radius | Max. flange thickness | |

| (kg) | (kg) | (mm) | Min | Max | (mm) | |||||||||||

| GMF1250/N 1Ph | 1250 | 14.4 | 30 | 215 | 62 | 209 | 250 | 241 | 183 | 23 | 49 | 167 | 70 | 240 | 1000 | 26 |

| GMF2500/N 1Ph | 2500 | 14.4 | 38 | 250 | 43 | 211 | 253 | 242 | 230 | 27 | 60 | 203 | 88 | 300 | 1500 | 30 |

| GMF1250/NF | 1250 | 14.4/4.8 | 30 | 239 | 49 | 175* | 329.5 | 273.5 | 186-286 | 31.5 | 48 | 179 | 70 | 240 | 1200 | 26 |

| GMF2500/NF | 2500 | 14.4/4.8 | 38 | 286 | 26 | 169 | 335.5 | 280.5 | 258-358 | 38 | 57 | 218 | 88 | 300 | 1500 | 30 |

| GMF4000/NF | 4000 | 14.4/4.8 | 55 | 341 | - | - | 338.5 | 282.5 | 268-368 | 40.5 | 57 | 241 | 91 | 300 | 1800 | 35 |

| GMF5000/NF | 5000 | 14.4/4.8 | 63 | 341 | - | - | 338.5 | 282.5 | 268-368 | 40.5 | 57 | 241 | 91 | 300 | 1800 | 35 |

| GMF6300/NF | 6300 | 14.4/4.8 | 78 | 387 | - | - | 344.5 | 289.5 | 292-392 | 46.5 | 54.5 | 270 | 91 | 000 | 1800 | 36 |