THE CARBON FIBER COMPOSITE CLAMP — The SpanSet Gladiator All-Direction Lifting Clamp is built for tough industrial demands, offering 360° flexibility for lifting, turning, and aligning heavy steel plates, beams, and structures. Its unique articulated lifting shackle and self-aligning cam ensure secure grip and optimal load distribution in any direction. Designed for safety, the Gladiator includes wear and overload indicators and is ideal for use on construction sites, shipyards, and steel fabrication plants. With a high-strength build and certified performance, this all-purpose lifting clamp combines German engineering with SpanSet’s trusted quality — for safe, versatile, and efficient material handling.

- Ultra lightweight and incredibly strong body made from carbon fiber composites.

- Horizontal and vertical lifting – Equiped with a horizontal and vertical hoisting eye.

- Better grip on the clamp while attaching it to the plate.

- Maximum WLL indicator, positions are clearly visible on both hoisting eyes.

- Fitted with a safe lifting indicator, which ensures sufficient clamping force.

Request a quote

High Performance - Features

- Made from carbon fiber composite materials.

By using carbon fiber composites we can produce ultra lightweight lifting clamps that are also incredibly strong, are corrosion-resistant and feature superb fatigue characteristics. - Equiped with a horizontal and vertical hoisting eye.

Due to this construction, the clamps are suitable for lifting, turning (180°), moving and transfer of sheet materials, plates, beams and fabrications in horizontal and vertical position. - Fitted with a safe lifting indicator, which ensures complete safety. When the clamp screw is tightened, the safe lifting indicator moves from the left (red) to the right (green) area. When the safe lifting indicator is in the green area there is sufficient clamping force to perform a safe lift.

- Breaking Load Limit of 4x WLL.

- Tested in horizontal and vertical position; 2,000,000 load cycles.

- For use with materials with a surface hardness up to 364 HV and material tensile strength up to 1200N/mm2.

- No minimum WLL required

- Individually serialised.

Serial number and date of proof load test are marked on the body. - Instruction manual and test certificate included with each clamp.

- Service and repair manual available on request.

- All load-bearing parts are marked with a traceability code and the HPLE logo to guarantee the original, highest-quality HPLE parts.

- Individually proof tested to 2x the Working Load Limit with certification.

- RFID-equipped.

- Temperature Range -40°C/104°F - +80°C/176°F.

Gladiator Norms

- USA Norm ASME B30.20, Design category B, Service class 4 / USA Norm ASME BTH – 1

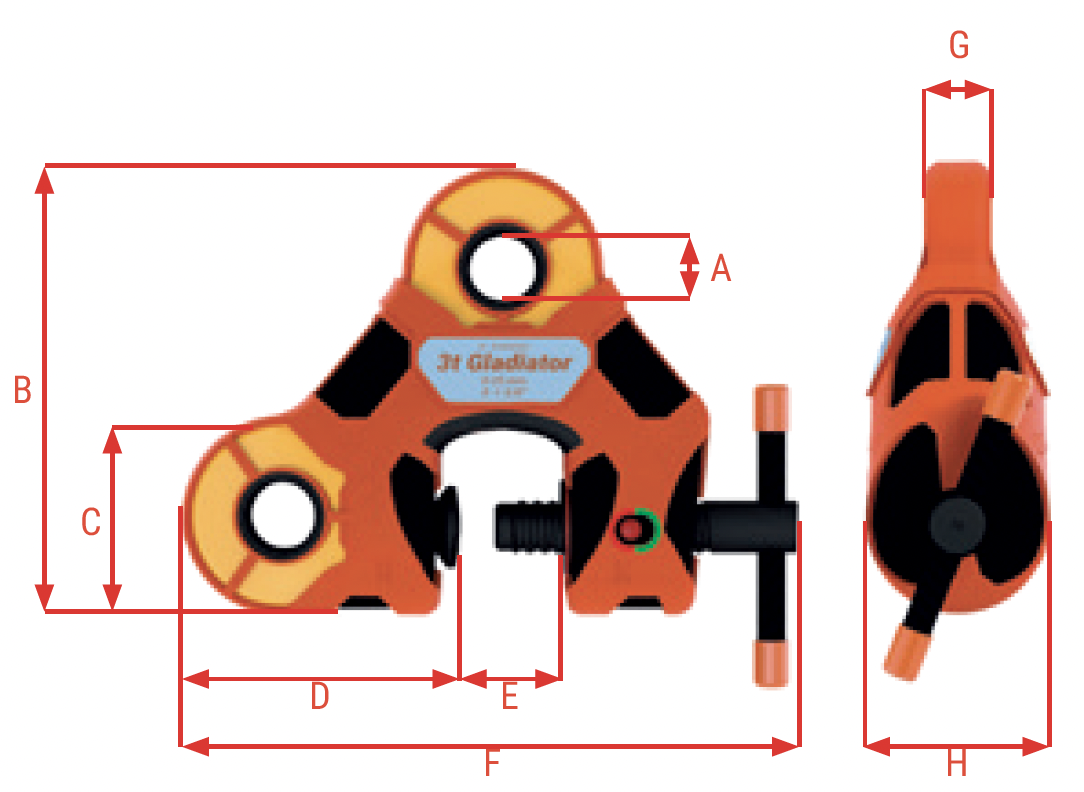

| |||||||||||

| Model | WLL(t) | Jaw aperture mm [in] | Dimensions mm [in] | Product weight [lb] | |||||||

| A | B | C | D | E | F | G | H | ||||

| 3-AD | 3 | 0-35 [0-1.34] | 30 [1.18] | 203 [7.99] | 96 [3.78] | 126 [4.96] | 62 [2.44] | 263 [10.35] | 32 [1.26] | 80 [3.15] | 3.6 [6.61] |

| 6-AD | 6 | 0-50 [0-1.97] | 38 [1.50] | 275 [10.83] | 125 [4.92] | 172 [6.77] | 65 [2.56] | 335 [13.19] | 57 [2.24] | 126 [4.96] | 9.7 [19.84] |

| For very hard materials | |||||||||||

| 3-AD H | 3 | 0-35 [0-1.34] | 30 [1.18] | 203 [7.99] | 96 [3.78] | 126 [4.96] | 62 [2.44] | 263 [10.35] | 32 [1.26] | 80 [3.15] | 3.6 [6.61] |

| 6-AD H | 6 | 0-50 [0-1.97] | 38 [1.50] | 275 [10.83] | 125 [4.92] | 172 [6.77] | 65 [2.56] | 335 [13.19] | 57 [2.24] | 126 [4.96] | 9.7 [19.84] |

| For stainless steel | |||||||||||

| 3-AD S | 3 | 0-35 [0-1.34] | 30 [1.18] | 203 [7.99] | 96 [3.78] | 126 [4.96] | 62 [2.44] | 263 [10.35] | 32 [1.26] | 80 [3.15] | 3.6 [6.61] |

| 6-AD S | 6 | 0-50 [0-1.97] | 38 [1.50] | 275 [10.83] | 125 [4.92] | 172 [6.77] | 65 [2.56] | 335 [13.19] | 57 [2.24] | 126 [4.96] | 9.7 [19.84] |